Solutions Of Heat Seal Testers For Reliable Packaging

In the realm of packaging, ensuring the integrity and quality of sealed products is paramount. This is where heat seal testers come into play. These innovative devices are designed to measure and evaluate the strength and effectiveness of heat seals in packaging materials.

In blog post, By understanding their capabilities, industrial professionals can make informed decisions when seeking reliable testing solutions to guarantee the performance and safety of their packaging processes.

Understanding Heat Seal Testers

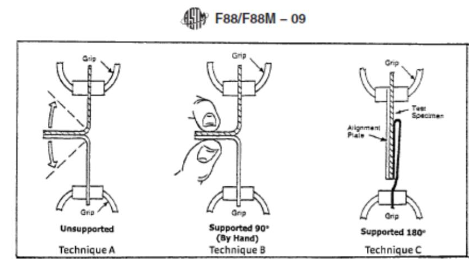

Heat seal testers by China heat seal tester suppliers are precision instruments that assess the quality and strength of heat seals. They simulate real-world conditions by subjecting sealed packaging samples to controlled temperatures, pressures, and dwell times. These testers measure parameters such as seal strength, seal integrity, peel strength, and burst strength, providing valuable data for quality control and process optimization. Heat seal testers employ various testing methods, including hot tack, peel, burst, and creep testing, depending on the specific requirements of the packaging application.

Features and Benefits Of Heat Seal Tester

Heat seal testers offer a multitude of features and benefits that make them indispensable in the packaging industry. Firstly, they ensure product safety by assessing the reliability and hermetic seal of packaging materials, preventing any potential contamination or spoilage. These testers provide quantitative results, enabling manufacturers to meet regulatory compliance and industry standards. By identifying weak seals and potential issues early in the production process, heat seal testers help minimize waste, reduce costs, and enhance overall operational efficiency. Additionally, they facilitate research and development efforts by allowing packaging engineers to optimize seal parameters and choose the most suitable materials for specific applications.

Applications in Packaging Heat Seal Testers

Heat seal testers find widespread usage across various packaging sectors, ensuring the quality and performance of seals in a wide range of materials. In the food and beverage industry, these testers verify the integrity of seals in pouches, trays, and blister packs, preserving freshness and preventing leaks. They are essential in pharmaceutical packaging, where seal strength and integrity are critical to maintaining product efficacy and safety. Heat seal testers are also utilized in the medical device industry, ensuring the integrity of sterile packaging and preventing contamination. Additionally, they play a crucial role in industries such as electronics, cosmetics, and consumer goods, where reliable seals are essential for product protection and consumer satisfaction.

Choosing The Proper Heat Seal Tester For Related Industry

Selecting the appropriate heat seal tester requires careful consideration of specific requirements and testing parameters. Factors such as seal material, seal width, temperature range, pressure range, and testing method should be taken into account. It is crucial to choose a heat seal tester that aligns with the packaging materials and industry standards. Reputable suppliers and manufacturers offer a range of models and configurations to accommodate different testing needs. Consulting with experts and conducting thorough research ensures the selection of a heat seal tester that meets the desired specifications and delivers accurate and reliable results.

Investing in Reliable Heat Seal Testers

Reliable heat seal testers can be obtained from authorized distributors, specialized testing equipment suppliers, or directly from manufacturers.

It is advisable to choose reputable suppliers that offer high-quality instruments, technical support, and after-sales service.

Consideration should also be given to factors such as warranty, calibration services, and software capabilities for data analysis and reporting.

Investing in a reliable heat seal tester not only ensures the quality and safety of packaged products but also contributes to long-term cost savings, improved customer satisfaction, and enhanced brand reputation.